In the ever-evolving landscape of industrial preservation, the importance of safeguarding metal assets from corrosion cannot be overstated. The advancements in technology have given rise to various methods, and among them, VCI films have emerged as a reliable and efficient solution. This post delves into the world of VCI films, unraveling their benefits and exploring their vital role in metal preservation.

Understanding the Threat: Corrosion’s Stealthy Onslaught

Metal corrosion is an insidious force that can silently compromise the integrity of structures, machinery, and various metal components. Whether it’s the expansive infrastructure of manufacturing plants, the intricate machinery of automotive industries, or the vital components of aerospace engineering, corrosion poses a constant threat.

The causes of corrosion are diverse, ranging from exposure to harsh environmental conditions, fluctuations in temperature and humidity, to the simple passage of time. Traditional methods of protection, such as oil coatings and desiccants, have their limitations, often proving ineffective in providing long-term, comprehensive defense against corrosion.

Enter VCI Films: A Shielding Innovation

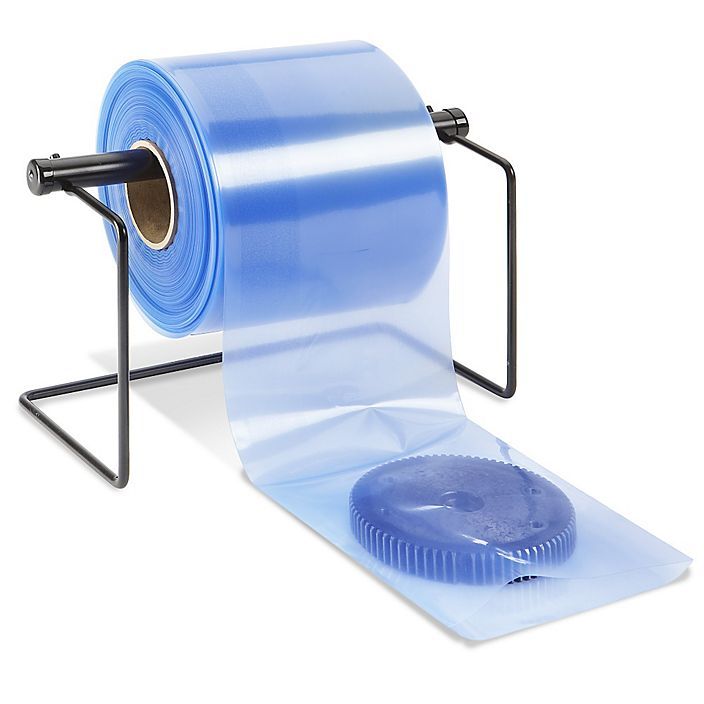

VCI films represent a breakthrough in the battle against corrosion. These films are specially engineered to release volatile corrosion inhibitors, forming an invisible protective shield around metal surfaces. The inhibitors vaporize and settle on the metal, creating a molecular barrier that prevents corrosion by interrupting the electrochemical reactions that lead to metal deterioration.

The Key Benefits of VCI Films:

- Corrosion Prevention: The primary and most crucial benefit of VCI films is their ability to prevent corrosion. By creating a protective atmosphere around the metal, these films act as a barrier against the corrosive elements present in the environment.

- Ease of Application: Applying VCI films is a straightforward process that requires minimal training. The films are available in various forms, including rolls, bags, and sheets, making them adaptable to different applications and sizes of metal assets.

- Long-Term Protection: Unlike some traditional methods that may provide only temporary relief, VCI films offer long-lasting protection. This makes them particularly valuable for assets in storage or during transportation, ensuring that the metal remains shielded from corrosion over extended periods.

- Environmentally Friendly: VCI films are often environmentally friendly, as they eliminate the need for toxic coatings and chemicals traditionally used in corrosion prevention. This aligns with the growing emphasis on sustainable practices in various industries.

- Versatility: VCI films are versatile and can be used across a wide range of industries. From the manufacturing sector to aerospace, automotive, and even military applications, these films have proven their efficacy in diverse environments.

The Future of Metal Preservation: Innovations in VCI Films

As technology continues to advance, so does the field of metal preservation. Researchers and manufacturers are constantly working to enhance the capabilities of VCI films, exploring new formulations and applications to address evolving challenges.

1. Smart VCI Films:

The integration of smart technology into VCI films is an exciting frontier. Researchers are exploring ways to incorporate sensors and monitoring devices directly into the films, allowing real-time tracking of environmental conditions and the effectiveness of the corrosion protection.

2. Customized Formulations:

Advancements in material science enable the customization of VCI film formulations to cater to specific metals and environmental conditions. This tailored approach ensures optimal protection, enhancing the overall efficacy of VCI films in diverse applications.

3. Nanotechnology Integration:

Nanotechnology holds promise in further improving the performance of VCI films. By leveraging nanomaterials, researchers aim to enhance the durability, adhesion, and overall protective qualities of these films, making them even more effective in harsh conditions.

Best Practices for VCI Film Application

To maximize the benefits of VCI films, industries must adopt best practices in their application. Here are some key considerations:

- Clean Surfaces: Ensure that metal surfaces are clean and free from contaminants before applying VCI films. Any residue or dirt on the metal can compromise the effectiveness of the protective barrier.

- Proper Storage: Store VCI films in a cool, dry place to maintain their integrity. Exposure to extreme temperatures or humidity can affect the performance of the films.

- Regular Inspection: Implement a regular inspection routine to check the condition of the VCI films and the protected metal surfaces. This proactive approach allows for early detection of any issues and ensures continuous protection.

- Adaptability: Choose the appropriate type of VCI film for the specific metal and application. Different formulations cater to varying needs, and selecting the right one is crucial for optimal protection.

- Collaboration with Suppliers: Establish open communication with VCI film suppliers. They can provide valuable insights, recommendations, and updates on new advancements in the field, ensuring that your metal preservation practices stay current.

Conclusion

In the world of metal preservation, where the battle against corrosion is ongoing, VCI films stand as stalwart defenders. Their ability to create an imperceptible shield around metal assets, preventing corrosion at the molecular level, has revolutionized the way industries approach metal protection.

As we look to the future, the continued innovation in VCI film technology holds the promise of even more effective and versatile solutions. Whether it’s through the integration of smart technologies, customization for specific applications, or the harnessing of nanotechnology, the evolution of VCI films is set to further enhance their role in preserving our valuable metal assets.

In embracing VCI films, industries not only shield their assets from corrosion but also contribute to a more sustainable and environmentally conscious approach to metal preservation. As we move forward, the collaboration between manufacturers, researchers, and end-users will undoubtedly lead to new frontiers in the quest to safeguard our metal legacy.