In the realm of industrial packaging, the protection of ferrous metals, particularly iron and steel, against corrosion is a paramount concern. The relentless battle against the corrosive forces of moisture, oxygen, and environmental contaminants requires innovative solutions. One such solution that has proven to be highly effective is VCI stretch film. In this comprehensive exploration, we will delve into the unique challenges posed by corrosion in ferrous metals and how VCI stretch film emerges as a tailored and robust solution for preventing corrosion in iron and steel.

Understanding the Ferrous Metals Challenge

1. Corrosion as a Menace

Ferrous metals, encompassing iron and steel, are widely used in various industries due to their strength and versatility. However, they are highly susceptible to corrosion, a natural process that leads to the deterioration of metals when exposed to environmental elements. Corrosion not only affects the appearance of metal surfaces but can also compromise the structural integrity of components, leading to functional failures and safety hazards.

2. Corrosion in Industrial Settings

In industrial settings, where ferrous metals are prevalent in machinery, equipment, and components, the impact of corrosion can be severe. The economic repercussions of replacing or repairing corroded parts, coupled with the potential for production downtime, underscore the urgency of implementing effective corrosion prevention strategies.

Enter VCI Stretch Film: A Tailored Solution for Ferrous Metals

1. How VCI Technology Targets Corrosion in Ferrous Metals

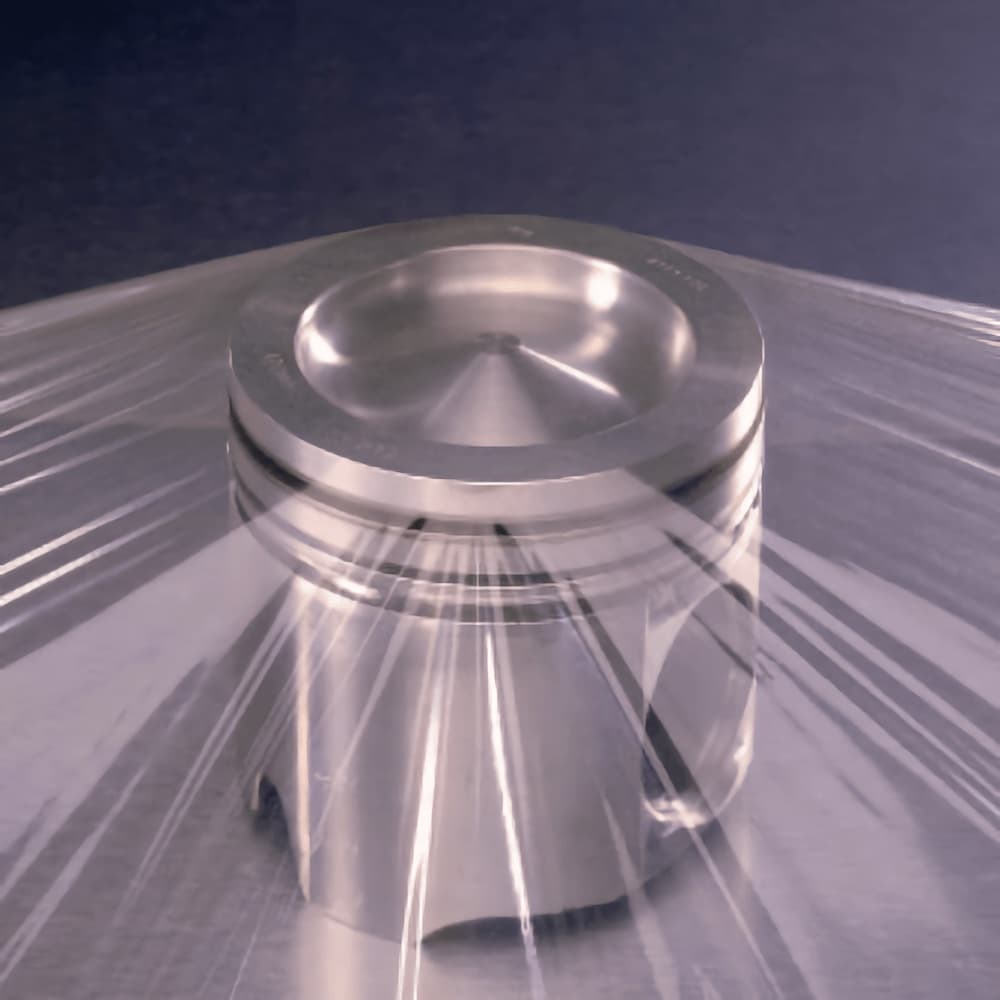

VCI stretch film introduces a sophisticated approach to corrosion prevention, specifically tailored to address the challenges posed by ferrous metals. The core of its effectiveness lies in the science of VCI technology. The film is impregnated with volatile corrosion inhibitors that, when released, form a protective molecular layer on the surface of ferrous metals.

1.1. Formation of a Protective Barrier

Upon wrapping ferrous metal items with VCI stretch film, the volatile corrosion inhibitors vaporize, creating a microenvironment that shields the metal from corrosive elements. This protective barrier acts as a deterrent against moisture, oxygen, and other contaminants that are known contributors to corrosion.

1.2. Contact and Vapor Phase Corrosion Inhibition

VCI stretch film employs a dual-action mechanism known as contact and vapor phase corrosion inhibition. Contact inhibition occurs when the VCI molecules come into direct contact with the metal surface, forming a protective layer. Vapor phase inhibition, on the other hand, involves the VCI molecules diffusing into the surrounding air and creating a corrosion-inhibiting atmosphere within the enclosed space.

2. Advantages of VCI Stretch Film for Ferrous Metals

2.1. Unparalleled Corrosion Protection

The primary advantage of VCI stretch film for ferrous metals is its unparalleled corrosion protection. The film’s ability to create a barrier against corrosive elements ensures that iron and steel components remain corrosion-free throughout their transportation and storage lifecycle.

2.2. Versatility in Application

VCI stretch film’s versatility extends to a wide range of applications within industries dealing with ferrous metals. From large machinery components in manufacturing plants to intricate parts in the automotive sector, the film adapts to diverse shapes and sizes, providing comprehensive corrosion protection.

2.3. Extended Storage Durability

By preventing corrosion, VCI stretch film contributes to the extended storage durability of ferrous metal products. This is particularly crucial for manufacturers and distributors dealing with long lead times, ensuring that products maintain their quality and performance characteristics when they reach end-users.

2.4. Reduced Maintenance Costs

The implementation of VCI stretch film translates to reduced maintenance costs for industries relying on ferrous metals. The film mitigates the need for frequent maintenance interventions and repairs associated with corrosion-related damage, leading to substantial cost savings over time.

3. Applications of VCI Stretch Film in Ferrous Metal Industries

3.1. Automotive Manufacturing

In the automotive manufacturing sector, where steel components are integral to the production of vehicles, VCI stretch film plays a vital role in preventing corrosion. Whether it’s engine parts, chassis components, or brake systems, the film ensures that these critical elements remain in optimal condition from the manufacturing line to the end-user.

3.2. Heavy Machinery and Equipment

Industries relying on heavy machinery and equipment, such as construction and mining, benefit significantly from VCI stretch film. The film protects exposed steel surfaces, preventing corrosion in harsh environments where these machines operate.

3.3. Infrastructure and Construction

In the construction industry, where steel is a fundamental building material, VCI stretch film safeguards structural components during transportation and on-site storage. This is particularly relevant for projects with extended timelines, preventing corrosion-related issues during the construction phase.

3.4. Metal Fabrication and Processing

Metal fabrication and processing facilities face the challenge of preserving the quality of finished metal products. VCI stretch film is employed to protect these products during transit and storage, ensuring that they reach customers in optimal condition.

Challenges and Considerations in Using VCI Stretch Film for Ferrous Metals

1. Compatibility with Other Packaging Materials

While VCI stretch film is highly effective in preventing corrosion, it’s essential to consider its compatibility with other packaging materials. Some materials may hinder the release of VCI molecules or interact negatively with the film, potentially impacting its performance.

2. Application Technique

The proper application of VCI stretch film is crucial for maximizing its effectiveness. Attention to wrapping techniques, ensuring a tight and secure seal, is necessary to create an effective protective barrier on ferrous metal surfaces.

3. Environmental Factors

Extreme environmental conditions, such as high temperatures or excessive humidity, can influence the performance of VCI stretch film. It’s important to take these factors into account when implementing corrosion prevention strategies in different geographic locations or climates.

Conclusion: A Tailored Defense Against Ferrous Metal Corrosion

In the relentless battle against corrosion in ferrous metals, VCI stretch film emerges as a tailored and formidable defense. Its unique combination of VCI technology, versatility, and cost-effectiveness makes it a preferred choice for industries dealing with iron and steel components.

As industrial landscapes continue to evolve, the need for smart and effective packaging solutions becomes increasingly evident. VCI stretch film not only addresses the immediate challenge of corrosion prevention but also contributes to the overall efficiency of supply chains by minimizing maintenance costs, extending storage durability, and ensuring that ferrous metal products reach their destination in optimal condition.

For industries where iron and steel are the backbone of production, investing in VCI stretch film is more than a protective measure—it’s a strategic decision that safeguards assets, enhances operational efficiency, and contributes to the longevity of valuable ferrous metal components. As technology continues to advance, VCI stretch film stands as a testament to innovation in packaging solutions, offering a tailored defense against the pervasive threat of corrosion in the world of ferrous metals.